For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

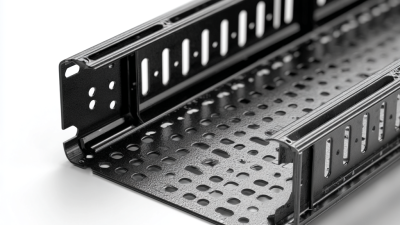

Exploring the Benefits and Innovations of Aluminum Cable Trays in Modern Electrical Installations

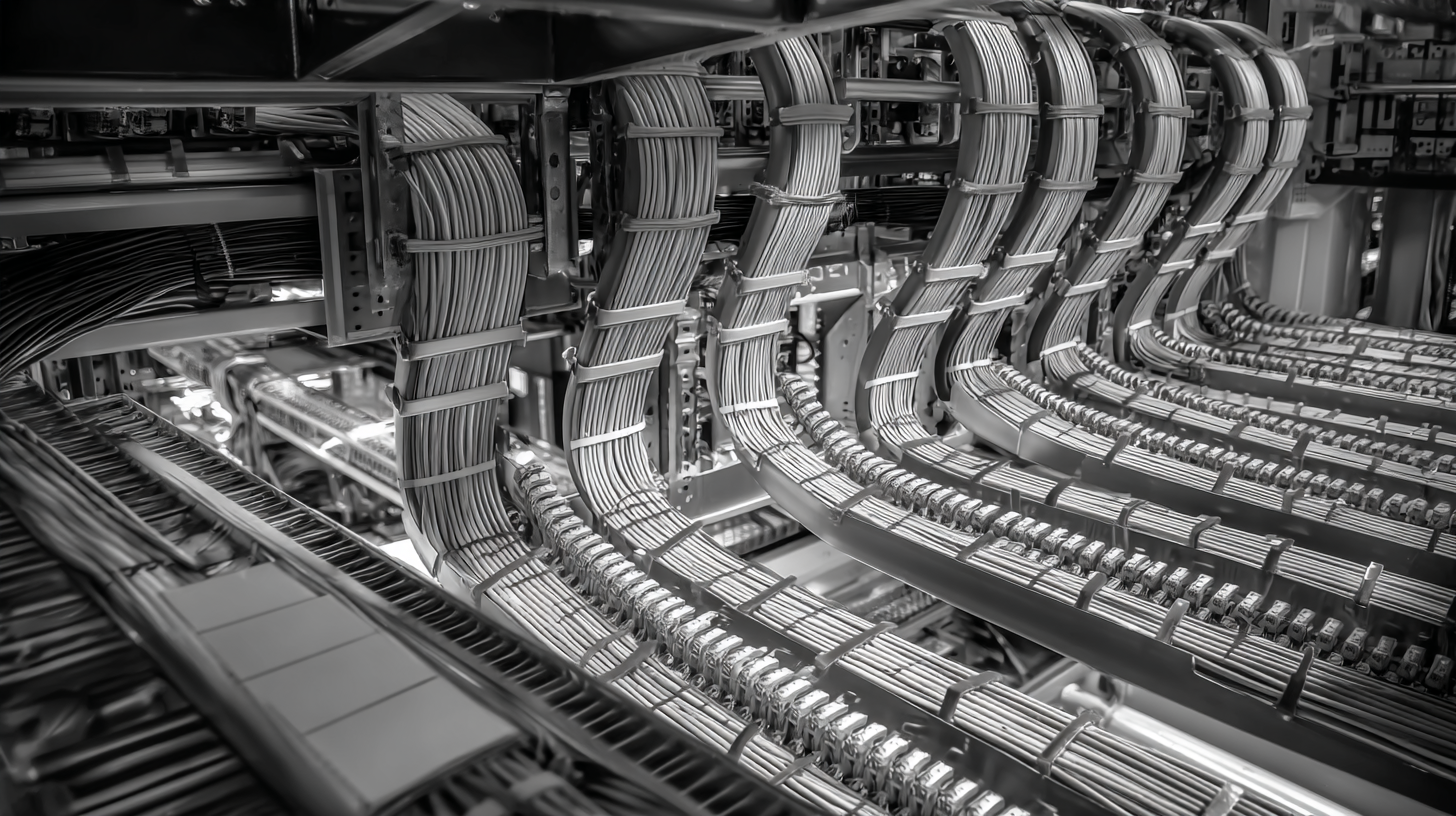

The growing demand for efficient and sustainable solutions in modern electrical installations has led to the increasing utilization of aluminum cable trays. These innovative products not only provide robust support for electrical wiring but also offer significant advantages over traditional materials. Aluminum cable trays are known for their lightweight properties, allowing for easier installation and reduced labor costs. Additionally, their resistance to corrosion and environmental factors ensures a longer lifespan, making them a cost-effective choice for both residential and commercial projects. As industries evolve and prioritize sustainability, the incorporation of aluminum cable trays is becoming a vital component in electrical design and implementation, aligning with the goals of reducing energy consumption and enhancing overall safety. This exploration delves into the numerous benefits and innovations associated with aluminum cable trays, highlighting their pivotal role in shaping the future of electrical installations.

The Advantages of Aluminum Cable Trays Over Traditional Materials

Aluminum cable trays are becoming increasingly popular in modern electrical installations, and for good reason. They offer several distinct advantages over traditional materials like steel and stainless steel. One of the most significant benefits is their lightweight nature, which not only makes them easier to transport and install but also reduces the overall weight burden on structures. This characteristic can lead to lower installation costs and more efficient project timelines. Furthermore, aluminum is highly resistant to corrosion, making it an ideal choice for environments that may expose cable trays to moisture or other corrosive elements.

When considering aluminum cable trays, it's essential to recognize their versatility and adaptability in various applications. They are suitable for both indoor and outdoor use, retaining durability and aesthetic appeal across different settings.

**Tips:** When planning your electrical installation, ensure that you consider the specific environmental conditions that your cable trays will face. Choosing the correct finish for aluminum trays can enhance their longevity and performance. Additionally, integrating proper cable management with aluminum trays can greatly improve the efficiency and safety of your installation.

Benefits of Aluminum Cable Trays Over Traditional Materials

This chart compares the benefits of aluminum cable trays against traditional materials across various criteria, illustrating the significant advantages that aluminum presents in modern electrical installations.

Innovative Designs of Aluminum Cable Trays Enhancing Installation Efficiency

Aluminum cable trays are gaining traction in modern electrical installations due to their innovative designs that enhance installation efficiency. Unlike traditional materials, aluminum offers a lightweight yet robust solution, simplifying handling and installation processes. The seamless integration of aluminum trays fosters quicker assembly times, allowing electrical contractors to reduce labor costs and improve overall project timelines. Additionally, aluminum's resistance to corrosion ensures a longer lifespan, which translates to lower maintenance expenses over time.

Tips for optimizing the installation of aluminum cable trays include ensuring proper alignment before securing the trays to avoid unnecessary rework later. Additionally, considering pre-fabricated components can further streamline the installation process, allowing for a more efficient setup. Utilizing modular designs can also be beneficial, as they provide flexibility in adapting to future modifications or expansions in electrical systems.

Incorporating innovative aluminum cable tray designs not only enhances the efficiency of installations but also improves safety and compliance with industry standards. As the cable tray market continues to evolve, embracing these advancements can significantly contribute to the success of electrical projects.

Exploring the Benefits and Innovations of Aluminum Cable Trays in Modern Electrical Installations

| Feature | Benefit | Innovation | Installation Efficiency |

|---|---|---|---|

| Lightweight Design | Easier handling and transport | Advanced aluminum alloy materials | Reduces labor costs |

| Corrosion Resistance | Increased lifespan in harsh conditions | Surface treatment technologies | Less frequent replacements |

| Sleek Aesthetic | Improves overall installation appearance | Modern design features | Attractive installations that appeal to clients |

| High Load Capacity | Supports heavier cables and equipment | Innovative structural designs | Reduces need for additional support structures |

| Modular Systems | Flexibility in installation | Interlocking components | Quick assembly and disassembly |

The Role of Aluminum Cable Trays in Modern Electrical Safety Standards

In contemporary electrical installations, aluminum cable trays play a crucial role in enhancing safety standards. As electrical systems become more complex, the need for robust and reliable cable management solutions has escalated. Aluminum cable trays, known for their lightweight yet strong properties, significantly contribute to the organized routing of electrical wiring. This organization directly supports compliance with modern electrical safety regulations by minimizing the risks of overheating and cable damage.

Moreover, the corrosion resistance of aluminum proves advantageous in various environments, ensuring longevity and reducing maintenance needs. The implementation of aluminum trays not only adheres to safety standards but also innovates the installation process. Their ease of handling and installation allows for quicker project completion, enhancing overall efficiency. Furthermore, with a growing emphasis on sustainability, aluminum's recyclability aligns with eco-friendly practices within electrical installations, making these tray systems a forward-thinking choice for builders and contractors alike.

Sustainability Benefits of Using Aluminum Cable Trays in Electrical Projects

Aluminum cable trays are gaining significant attention in modern electrical installations due to their sustainability benefits. Unlike traditional materials such as steel or plastic, aluminum is highly recyclable, with studies indicating that up to 90% of aluminum used in construction can be recycled without losing its properties. According to a report by the International Aluminum Institute, the recycling of aluminum saves up to 95% of the energy required to create new aluminum, resulting in a substantial reduction in carbon emissions, which is critical in achieving green building certifications.

Moreover, aluminum's lightweight nature contributes to lower transportation costs and easier installation processes, reducing the overall energy consumption associated with logistical operations. A recent study by the Electrical Contractors Association reported that using aluminum cable trays can decrease installation time by approximately 30%, allowing projects to adhere more closely to environmental timelines and practices. With properties such as corrosion resistance and durability, aluminum cable trays not only support sustainability initiatives but also enhance long-term cost-effectiveness in installations, making them an attractive option for electrical projects aiming for eco-friendliness.

Cost-Effectiveness of Aluminum Cable Trays in Long-Term Electrical Installations

Aluminum cable trays are gaining traction in modern electrical installations due to their cost-effectiveness, particularly in long-term applications. Unlike traditional materials such as steel, aluminum is lighter, which simplifies handling and installation, ultimately reducing labor costs. Additionally, aluminum's inherent resistance to corrosion extends the lifespan of cable management systems, decreasing the frequency of replacements and maintenance over time. This durability becomes increasingly relevant as organizations focus on sustainable practices and minimizing total lifetime costs.

The market analysis indicates a shift towards the utilization of aluminum in cable tray systems, as it offers both economic and environmental benefits. The growth projection for aluminum cable trays reflects a robust demand, driven by advancements in technology and an emphasis on energy-efficient solutions. As the industry continues to evolve, innovations in aluminum cable trays are likely to enhance their adaptability, making them a preferred choice for various electrical installation projects, ultimately supporting long-term cost savings and increased performance.

Related Posts

-

Ultimate Checklist for Choosing the Best Metal Cable Tray for Your Project Needs

-

China Leads the Global Market with Best Cable Tray Covers for Unmatched Quality

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

Understanding Import and Export Certifications for the Best Stainless Steel Cable Tray

-

Choosing the Right Metal Cable Tray for Your Specific Needs

-

Ultimate Guide to Electrical Cable Trays: Optimizing Efficiency and Safety in Modern Installations