For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

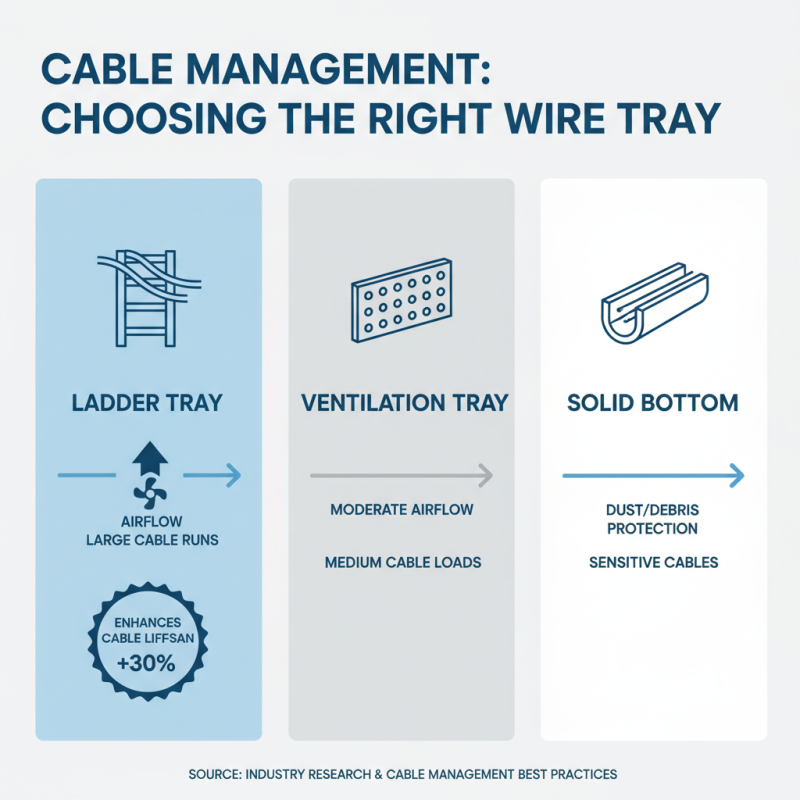

How to Choose the Right Wire Tray for Your Cable Management Needs?

Selecting an appropriate wire tray for cable management is an essential process for many industries. A recent industry report indicates that improper cable management can lead to a 30% increase in maintenance costs. The right wire tray not only organizes cables but also enhances safety and efficiency in electrical installations.

Expert John Smith, a leading figure in cable management solutions, emphasizes, "Choosing the right wire tray is crucial for both performance and safety." His insights echo widely among professionals who understand the importance of proper installation.

However, the sheer variety of wire trays available can overwhelm decision-makers. Factors such as size, material, and load capacity should all influence your choice. Often, companies may overlook specifics, leading to potential pitfalls in installation. Ensuring the right fit for your project can prevent future challenges and promote a streamlined operation.

Understanding Different Types of Wire Trays for Cable Management

When it comes to cable management, choosing the right wire tray is crucial. The main types include ladder trays, ventilation trays, and solid bottom trays. Each type serves a different purpose and environment. For instance, a ladder tray supports large cable runs and allows for airflow, reducing overheating risks. Research indicates that proper airflow can enhance cable lifespan by up to 30%.

The materials used also affect performance. Aluminum trays are lightweight but may not handle heavy loads. Steel trays are robust but can be quite heavy. The right choice depends on the specific weight and environmental requirements of your installation. A report from the National Electrical Contractors Association highlights that 68% of installation failures stem from improper cable management solutions.

Additionally, the size and spacing of wire trays can impact installation efficiency. If trays are too small, cables may become tangled. A clear understanding of your space is essential. Measure carefully to avoid common installation errors. Remember, even a small miscalculation can lead to significant issues down the line. Consider these factors thoroughly before making a choice.

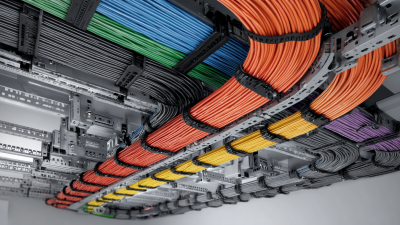

Assessing Your Cable Management Requirements and Environment

Choosing the right wire tray involves understanding your specific cable management needs. According to a report by the Institute of Electrical and Electronics Engineers, improper cable management can lead to a 30% decrease in system efficiency. Inadequate support for cables can lead to overheating, increased wear, and ultimately, equipment failure.

Assessing your environment is critical. Consider factors like cable volume, type, and the physical space available. For instance, a data center may require a different system than an industrial setting. The National Fire Protection Association states that poorly managed cables can increase fire risks by 60%. This highlights the importance of a proper wire tray system that fits your location and cable load.

Reflecting on your current setup can reveal hidden issues. Are cables tangled or overcrowded? It’s common to overlook these details. Users often underestimate the impact of layout changes on cable management. Small adjustments can lead to significant improvements. Recognizing these aspects will pave the way for a more effective and safe cable management solution.

Factors to Consider When Selecting a Wire Tray Material

Choosing the right wire tray material involves several crucial factors. First, consider the environment where the tray will be installed. Outdoor settings may require materials resistant to weather and UV exposure. Indoor installations might prioritize aesthetics and safety. A blend of metal and plastic could work in various environments, but each has its limitations.

Durability is vital. Metal trays are sturdy but can corrode if exposed to moisture. Plastic is lighter and more resilient to rust, but may not support heavy cables. Make sure to assess the weight of your cables. If they are heavy, a reinforced metal tray could be necessary.

Think about installation too. Some materials are easier to cut and shape than others. Complexity in installation can lead to higher labor costs. If you're planning a DIY project, lightweight options might be more user-friendly. Reflect on these aspects carefully. Each choice has trade-offs that could impact your overall cable management success.

Evaluating the Size and Capacity Needs for Wire Trays

Choosing the right wire tray for cable management requires careful evaluation of size and capacity. When planning, consider the volume and type of cables you need to manage. For example, a study by the National Electrical Contractors Association shows that 70% of installations fail due to inadequate planning. This highlights the importance of selecting the right size tray.

When measuring, you should account for both current and future needs. Make sure to consider cable type and diameter. Many professionals recommend allowing at least 25% extra capacity. This extra space prevents overheating and promotes airflow, which enhances performance.

Tips: Always remember to factor in bends and turns when calculating the total length of wire trays needed. Particularly in complex environments, such as data centers, miscalculations can lead to chaos. It is essential to revisit your design periodically. Reflect on whether your current tray system meets both organizational and safety standards. Regular reviews lead to better solutions.

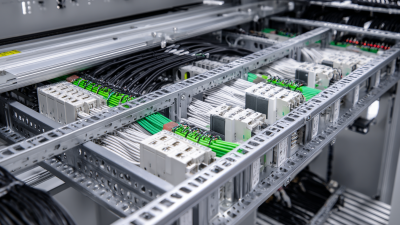

Installation Techniques and Best Practices for Wire Trays

When selecting wire trays for cable management, installation techniques greatly influence efficiency. Proper installation ensures safety and accessibility. Reports indicate that up to 20% of cable management issues stem from poorly installed trays. Tight spaces often complicate the process. Proper planning can mitigate these challenges.

One common error is overlooking load capacity. Wire trays must support the weight of cables without sagging. A study revealed that incorrect load distribution can reduce a tray's lifespan by 30%. Also, regular maintenance checks are crucial. Dust and debris can build up, leading to potential hazards.

Using proper tools during installation can enhance the outcome. Beginners may struggle with alignment, resulting in future adjustments. Fasteners should be tightened adequately. Loose fittings can lead to unwanted shifts. Emphasizing these details is essential for a robust installation process.

Related Posts

-

Top Strategies for Maximizing Efficiency with Wire Trays in Your Facility

-

Innovative Solutions for Cable Management Issues in Power Plant Applications Using Best Wire Tray

-

2026 How to Organize Your Space with Wire Tray Solutions?

-

Ultimate Checklist for Choosing the Best Metal Cable Tray for Your Project Needs

-

7 Essential Features of the Best Wire Raceway for Optimal Cable Management

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization