For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

7 Essential Tips for Choosing the Right Cable Tray Systems for Your Project

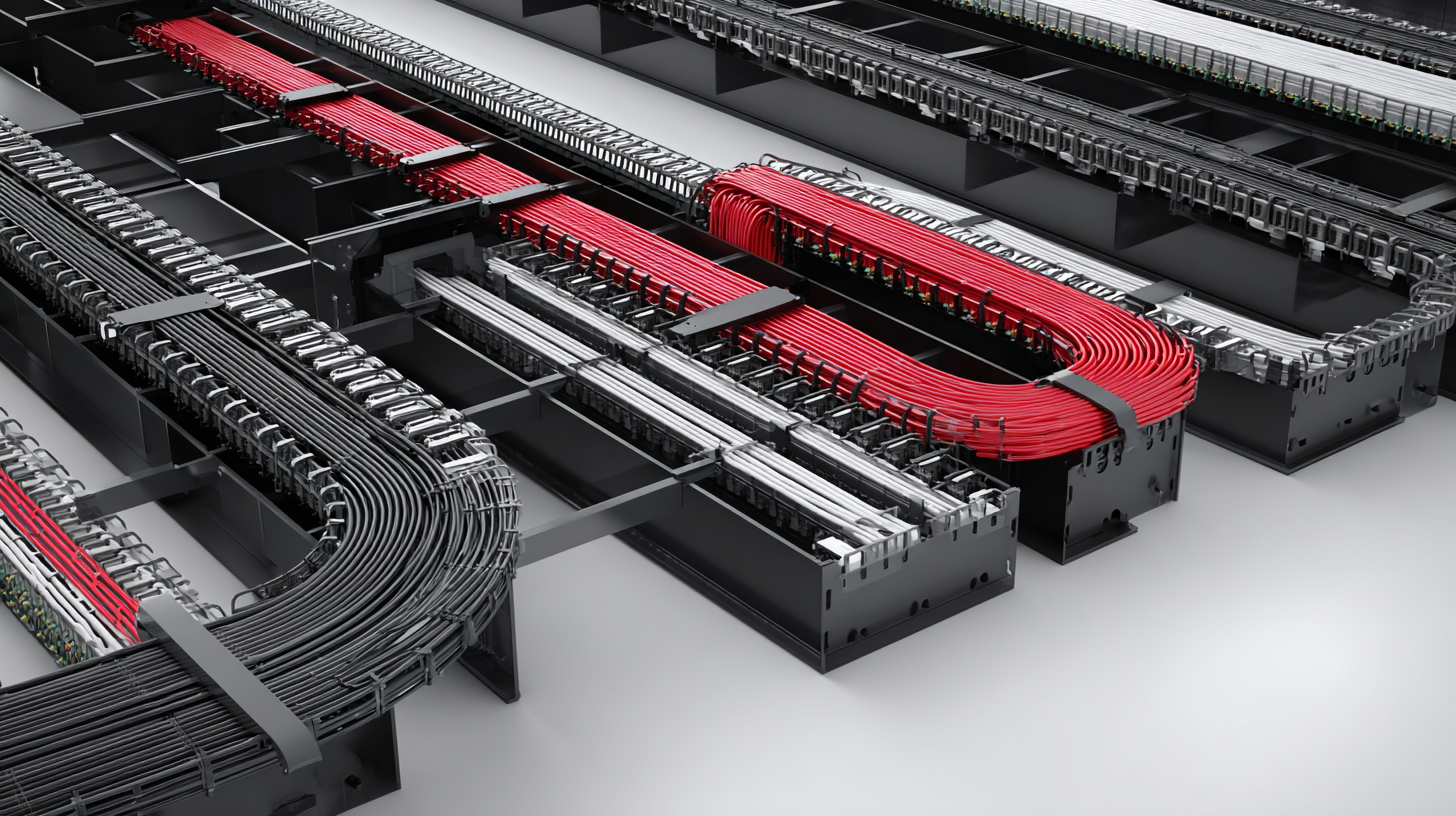

When it comes to managing electrical and communication cables in any project, selecting the appropriate cable tray systems is crucial for ensuring efficiency, safety, and ease of maintenance. Cable tray systems serve as the backbone for organizing and supporting wiring infrastructures, offering a range of benefits from accessibility to protection against environmental factors. However, with a multitude of options available in the market, determining the right type of cable tray systems can be overwhelming. This guide aims to simplify the decision-making process by providing you with seven essential tips that will help you navigate through the various factors to consider, ensuring you make an informed choice that aligns with the specific needs of your project. Whether designing a commercial building, an industrial facility, or a residential complex, the right cable tray systems play an integral role in enhancing operational efficiency and promoting longevity.

Benefits of Using Cable Tray Systems for Enhanced Cable Management Efficiency

When managing electrical cables for any project, the efficiency of your setup can significantly influence overall operations. Cable tray systems provide a structured pathway for organizing and supporting cables, reducing clutter while enhancing safety. By utilizing these systems, projects can experience improved cable management efficiency, preventing accidents and facilitating maintenance tasks.

One essential tip for choosing the right cable tray is to assess the load requirements. Ensure that the tray can accommodate the volume and weight of the cables you plan to install. Additionally, considering the environment where the cable trays will be installed is crucial. For instance, in areas prone to moisture, opt for trays made of corrosion-resistant materials.

Another key consideration is the layout and accessibility of the trays. Proper planning for cable routing not only simplifies installation but also ensures that technicians can easily access the cables for maintenance or upgrades. Implementing a well-thought-out design can save time and resources in the long run, further maximizing the benefits of using cable tray systems.

Understanding the Impact of Material Choice on Cable Tray Lifespan and Performance

When selecting cable tray systems for your project, understanding the impact of material choice on lifespan and performance is crucial. Different materials can significantly influence durability and maintenance needs. For instance, according to a recent industry report by the National Electrical Manufacturers Association (NEMA), galvanized steel cable trays can last up to 20 years in non-corrosive environments, while aluminum trays offer a lighter option with a lifespan of approximately 15 years. However, in highly corrosive settings, stainless steel trays might be more suitable despite their higher initial cost, providing an expected lifespan of over 30 years due to their superior resistance.

Tip: Always consider the environmental conditions where your cable trays will be installed. Choosing a material that aligns with the specific conditions can prevent costly replacements. Coupled with performance, the choice of the tray material affects not just longevity but also efficiency. A study from the International Electrotechnical Commission (IEC) highlighted that improper material selection could lead to overheating, reducing the electrical performance of cables housed within trays.

Tip: Evaluate the weight and load capacity of your selected tray material. For heavy-duty applications, ensure the tray can support the expected load without compromising safety. This consideration is essential as lightweight materials might not sustain the structural integrity required under heavy installations, emphasizing the need for thorough analysis during the selection process.

7 Essential Tips for Choosing the Right Cable Tray Systems for Your Project

| Material | Lifespan (Years) | Corrosion Resistance | Load Capacity (lbs) | Fire Rating |

|---|---|---|---|---|

| Steel | 10-20 | Moderate | 300 | Class A |

| Aluminum | 15-25 | High | 200 | Class B |

| Fiberglass | 20-30 | Excellent | 150 | Class C |

| PVC | 10-15 | Good | 100 | Class D |

Evaluating Load Capacity: Ensuring Cable Tray Systems Meet Project Demands

When evaluating load capacity for cable tray systems, it is crucial to ensure they meet the specific demands of your project. With the ongoing investments in the US power grid and the increasing consumption of electricity, the right cable management solutions have become more critical than ever.  As utilities and private companies ramp up their infrastructure to support soaring power demands, choosing a cable tray system that can handle high load capacities is essential. This includes considering not only the weight of the cables themselves but also any additional factors such as environmental changes or potential future expansion.

As utilities and private companies ramp up their infrastructure to support soaring power demands, choosing a cable tray system that can handle high load capacities is essential. This includes considering not only the weight of the cables themselves but also any additional factors such as environmental changes or potential future expansion.

Moreover, as new technologies and projects emerge, such as offshore renewable energy systems and advanced construction equipment, the requirements for cable management are evolving. It's important to assess the structural integrity and reliability of your chosen cable tray system in relation to these innovations. A well-chosen cable tray system will not only comply with current industry standards but will also anticipate future demands, providing a resilient solution that supports both electrical management and the overall efficiency of your project.

The Role of Cable Tray Systems in Compliance with Industry Safety Standards

When selecting cable tray systems for your project, understanding their role in compliance with industry safety standards is crucial. Cable trays are not merely conduits for electrical wires; they also play a vital role in ensuring that installations meet regulatory requirements. Proper selection and installation of these systems aid in providing safe pathways for electrical wires while minimizing hazards related to overheating, electrical fires, and physical damage.

Compliance with industry standards such as the National Electrical Code (NEC) and International Electrotechnical Commission (IEC) specifications ensures that cable tray systems are designed and constructed to withstand various stresses. When choosing a cable tray, it is important to consider factors including load capacity, material specifications, and environmental conditions. By adhering to these safety standards, businesses can avoid costly fines and enhance overall workplace safety, providing peace of mind for both employers and employees. Investing time in selecting the right cable tray system not only fosters compliance but also promotes a culture of safety that can have lasting benefits for any organization.

Cable Tray Systems Compliance with Industry Safety Standards

Optimizing Installation Time and Costs with Modular Cable Tray Solutions

When it comes to optimizing installation time and costs in cable management, modular cable tray solutions stand out as an effective strategy. According to a 2022 report by the National Electrical Manufacturers Association (NEMA), utilizing modular cable trays can reduce installation time by up to 30% compared to traditional systems. This efficiency is largely attributed to their customizable design, allowing for easy assembly and adaptability to various project requirements.

Additionally, modular cable trays facilitate the efficient management of electrical and data cables, which is critical in minimizing project delays. A study by the International Electrical & Electronics Engineers (IEEE) highlighted that improper cable management could lead to a 20% increase in overall project costs due to delays and potential rework. By choosing modular systems, project managers can streamline the installation process, mitigate risks associated with poor planning, and ensure better compliance with safety regulations, ultimately leading to significant cost savings throughout the project's lifecycle.