For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

Innovative Solutions for Cable Management Issues in Power Plant Applications Using Best Wire Tray

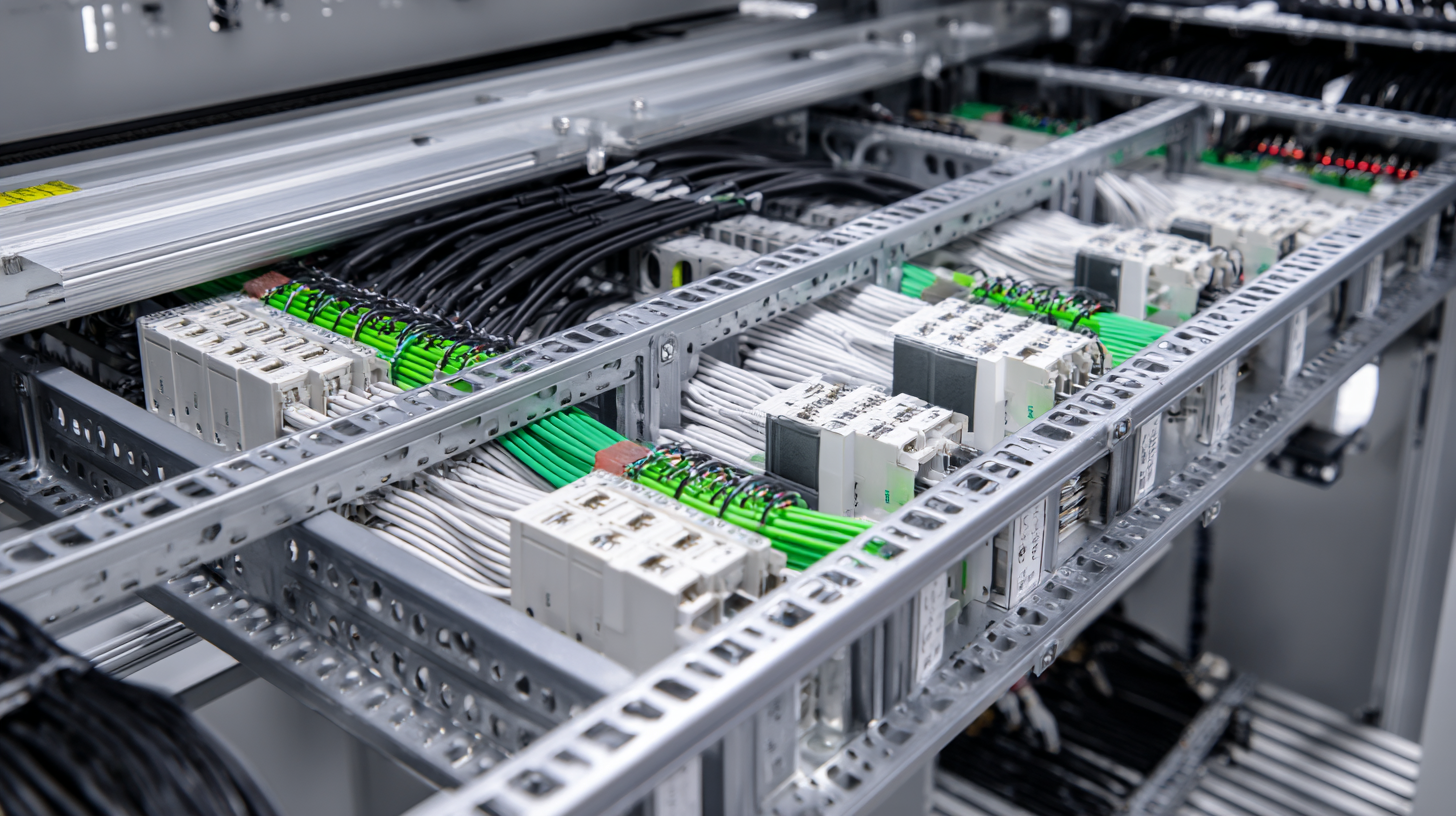

In the realm of power plant applications, effective cable management is critical to ensuring operational efficiency and safety. Among the myriad of solutions available, wire trays have emerged as a highly regarded choice for organizing and supporting electrical cables. This blog explores innovative solutions for addressing cable management challenges, with a particular focus on the best practices related to wire trays. By adhering to industry production standards and employing proven methodologies, power plant operators can significantly enhance their cable management systems.

We will delve into various types of wire trays, their construction materials, and installation techniques, providing actionable insights on how to optimize cable routing and protection within complex power generation environments. Join us as we navigate the essential considerations for selecting and implementing the most effective wire tray solutions that cater to the unique demands of power plants.

Identifying Key Factors to Select a Quality Wire Tray Manufacturer for Power Plants

When selecting a quality wire tray manufacturer for power plant applications, it's essential to focus on specific key factors that ensure durability, functionality, and safety. One crucial aspect is the material quality of the wire trays. Opt for manufacturers that use high-grade materials, such as stainless steel or aluminum, which can withstand harsh environmental conditions typical in power plants. Additionally, consider the manufacturer’s adherence to industry standards and certifications, as this can be a testament to their commitment to quality and safety.

**Tip 1:** Always request samples to evaluate the wire tray’s finish, strength, and corrosion resistance before placing a bulk order.

Another important factor is the manufacturer's experience and reputation in the industry. An established manufacturer with a solid track record can provide valuable insights into innovative solutions tailored for specific power plant challenges. Investigate client testimonials and case studies, as they can illuminate the manufacturer’s reliability and customer service.

**Tip 2:** Engage with the manufacturer’s technical support team to assess their expertise. A responsive and knowledgeable team can be a significant asset during installation and maintenance phases.

Innovative Solutions for Cable Management in Power Plants

Innovative Cable Management Strategies to Enhance Efficiency in Power Plant Operations

In the ever-evolving landscape of power plant operations, effective cable management has become critical for enhancing efficiency and safety. According to the 2022 Electrical Power Equipment Market Report, inefficient cable management can lead to a reduction in operational efficiency by as much as 20%. Innovative cable management strategies using high-quality wire trays can significantly mitigate these challenges. Well-designed wire trays not only organize and support electrical cables but also facilitate air circulation, reducing overheating and downtime.

Moreover, advancements in materials and designs of wire trays have paved the way for more resilient and flexible cable management solutions. For instance, the Global Power Generation Market Insight Report highlights that the adoption of lightweight, corrosion-resistant wire trays can lead to a 15% decrease in maintenance costs over a five-year period. By implementing these innovative strategies, power plants can optimize their operations, ensuring minimal disruption while adhering to safety standards and regulatory requirements. With the right tools and techniques, enhancing efficiency through effective cable management is within reach for every power plant operator.

Innovative Solutions for Cable Management Issues in Power Plant Applications Using Best Wire Tray

| Dimension | Description | Impact | Example Solution |

|---|---|---|---|

| Cable Organization | Arranging cables systematically for easy identification. | Reduces maintenance time and enhances safety. | Use of color-coded wire trays. |

| Space Utilization | Maximizing use of vertical and horizontal space in power plants. | Increases efficiency by reducing clutter. | Installing multi-tiered trays. |

| Cable Protection | Shielding cables from environmental hazards. | Enhances the lifespan of cables and reduces outages. | Using heavy-duty industrial trays. |

| Easy Access | Allowing technicians easy access to cables for repairs. | Speeds up troubleshooting and maintenance processes. | Implementing removable tray covers. |

| Compliance | Ensuring that cable management meets industry safety standards. | Avoids legal issues and enhances safety protocols. | Adopting standardized wire management systems. |

Evaluating Different Types of Wire Trays for Optimal Performance in Power Applications

In power plant applications, effective cable management is crucial for safety and operational efficiency. Evaluating different types of wire trays is essential to ensure optimal performance. According to the National Electrical Manufacturers Association (NEMA), over 60% of electrical hazards in industrial settings can be traced back to poor cable management practices. Selecting the right wire tray not only enhances safety but also aids in maintaining system integrity and minimizing downtime.

When choosing wire trays, consider materials that can withstand the harsh conditions often found in power plants. For instance, stainless steel trays offer superior durability and corrosion resistance, making them ideal for environments exposed to moisture and chemicals. Additionally, open wire tray designs facilitate airflow around cables, reducing the risk of overheating.

Tip: Regularly inspect your cable management systems and ensure that all accessories, including supports and connectors, are compatible with the selected wire tray type.

Optimizing cable layout can lead to increased efficiency in power applications, as a well-organized system simplifies maintenance and troubleshooting. Use data from industry experts to guide your selection process, ensuring that you choose trays designed for the specific load and environmental conditions they will face.

Tip: Keep cable lengths to a minimum to reduce installation time and improve performance.

Case Studies: Successful Implementations of Wire Tray Solutions in Power Plants

Effective cable management is crucial for maintaining the operational efficiency of power plants. In recent case studies, the implementation of innovative wire tray solutions has proven to be a significant advancement in addressing common cable management challenges. These solutions not only streamline the installation process but also enhance the safety and longevity of electrical systems. For instance, the use of sturdy and adaptable wire trays in various power plant scenarios has demonstrated marked improvements in organizing cables, reducing risk factors associated with cable damage, and optimizing maintenance protocols.

The benefits of these wire tray systems have been showcased through multiple successful implementations across different power plants. Each case highlights how tailored wire tray configurations support the unique needs of rural electrification projects, effectively managing complex cable layouts and providing robust support structures. As the energy sector continues to evolve, the integration of best practices in cable management, as highlighted by recent reviews, is essential for driving efficiency and reliability in power plant operations. These compelling case studies serve as a testament to the importance of innovative solutions in enhancing infrastructure resilience.

Future Trends in Cable Management for Power Plants: Innovations and Best Practices

In the rapidly evolving landscape of power plant operations, effective cable management is gaining significant attention. According to a report by the International Energy Agency (IEA), optimizing cable management can enhance operational efficiency and reduce maintenance costs by up to 30%. Future trends indicate a shift towards integrated cable management systems that leverage smart technologies. These systems are designed to monitor cable conditions in real-time, ensuring uninterrupted power transmission and minimizing downtime.

Tip: Regularly assess your existing cable management strategy to identify areas for improvement. Incorporating advanced wire trays that promote airflow can significantly extend cable life and improve performance.

Innovations in materials and designs are also paving the way for more sustainable practices in power plant cable management. Utilizing corrosion-resistant alloys and lightweight composites not only enhances durability but also contributes to the reduction of energy consumption during manufacturing. The global cable management market is projected to reach USD 4.18 billion by 2026, underscoring the increasing recognition of its importance.

Innovations in materials and designs are also paving the way for more sustainable practices in power plant cable management. Utilizing corrosion-resistant alloys and lightweight composites not only enhances durability but also contributes to the reduction of energy consumption during manufacturing. The global cable management market is projected to reach USD 4.18 billion by 2026, underscoring the increasing recognition of its importance.

Tip: Consider implementing flexible cable tray systems that can adapt to changing plant layouts, facilitating both maintenance and future expansions. This proactive approach to cable management aligns with best practices and positions power plants to meet future demands efficiently.