For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Cable Tray Brackets for Your Projects

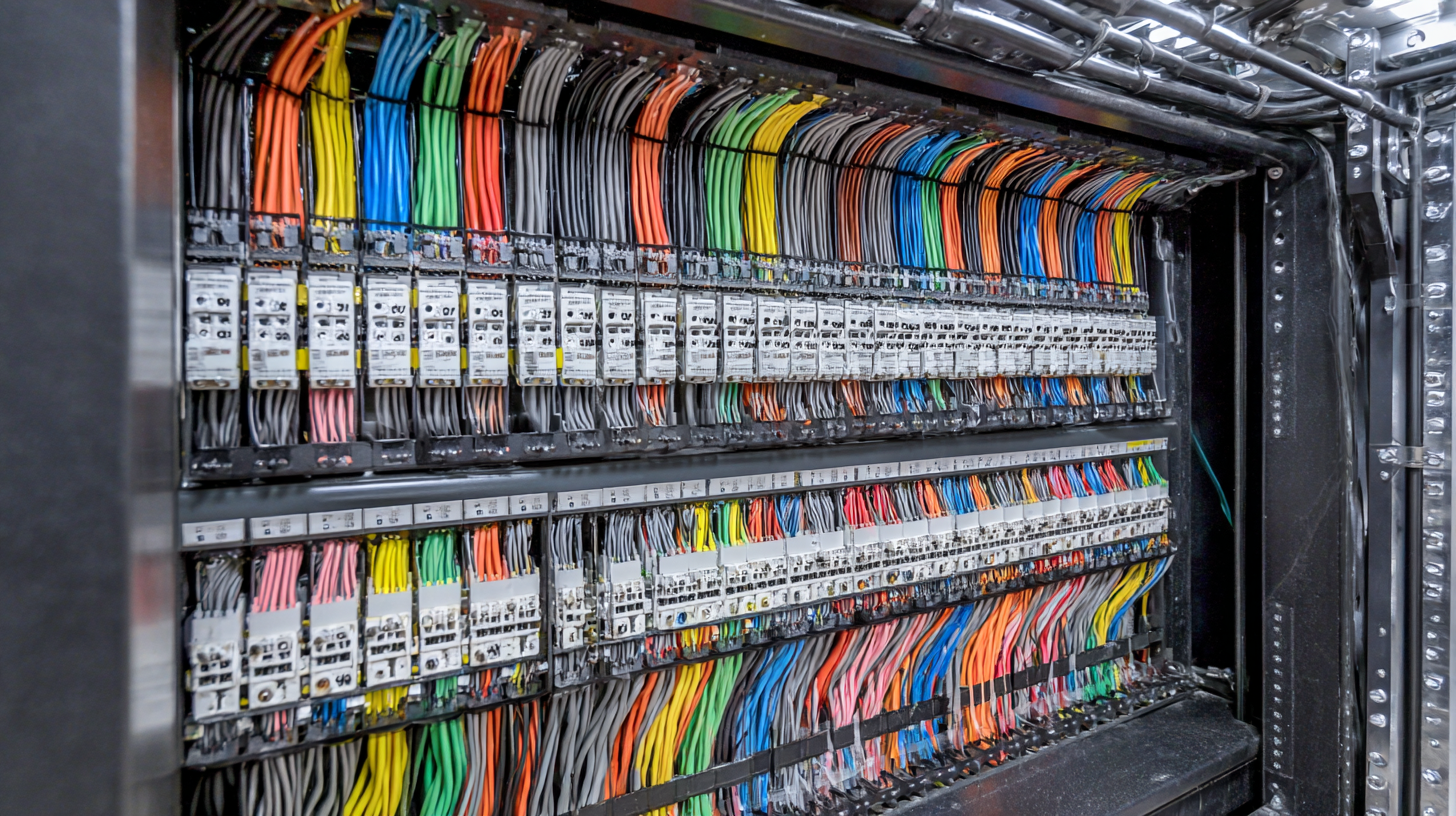

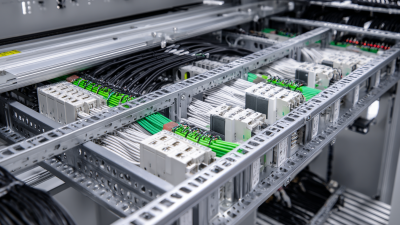

In the world of electrical installations and data management, the selection of appropriate cable tray brackets is critical for ensuring both safety and efficiency in your projects. Cable tray brackets serve as essential support structures that help organize and secure a network of cables, facilitating easy access for maintenance while minimizing the risk of damage. As projects vary in scope and specifications, understanding the different types of cable tray brackets available is crucial for optimizing installation processes. This guide delves into the various types of cable tray brackets, their applications, and key considerations to help you make informed choices that enhance the overall effectiveness of your projects. Whether you are working on a large industrial installation or a smaller commercial setup, the right cable tray brackets can significantly impact your workflow and operational efficiency.

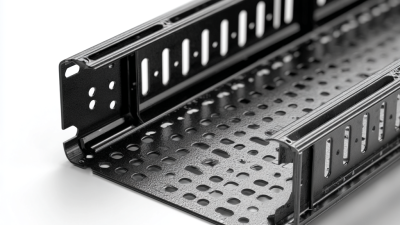

Understanding Cable Tray Bracket Types: A Comprehensive Overview

When it comes to choosing cable tray brackets for your project, understanding the different types available is crucial for maximizing efficiency. There are several common types of cable tray brackets, including ladder, solid bottom, trough, and channel brackets. Each type serves a specific purpose and is designed for varying applications within electrical installations. For example, ladder brackets are ideal for supporting cables in larger overhead spaces, while solid bottom brackets provide more protection for sensitive cables that require additional support and shielding.

Industry reports indicate that the global cable tray market is projected to experience significant growth, with a market size forecasted to increase from $253.48 million in 2019 to an estimated $696.78 million by 2032, showcasing a compound annual growth rate (CAGR) of 8.36%. This surge highlights the increasing demand for efficient cable management solutions across various sectors, including data centers and industrial settings. Choosing the right type of cable tray bracket ensures not only optimal performance but also aligns with the evolving standards of safety and efficiency in electrical installations.

Key Factors to Consider When Selecting Cable Tray Brackets

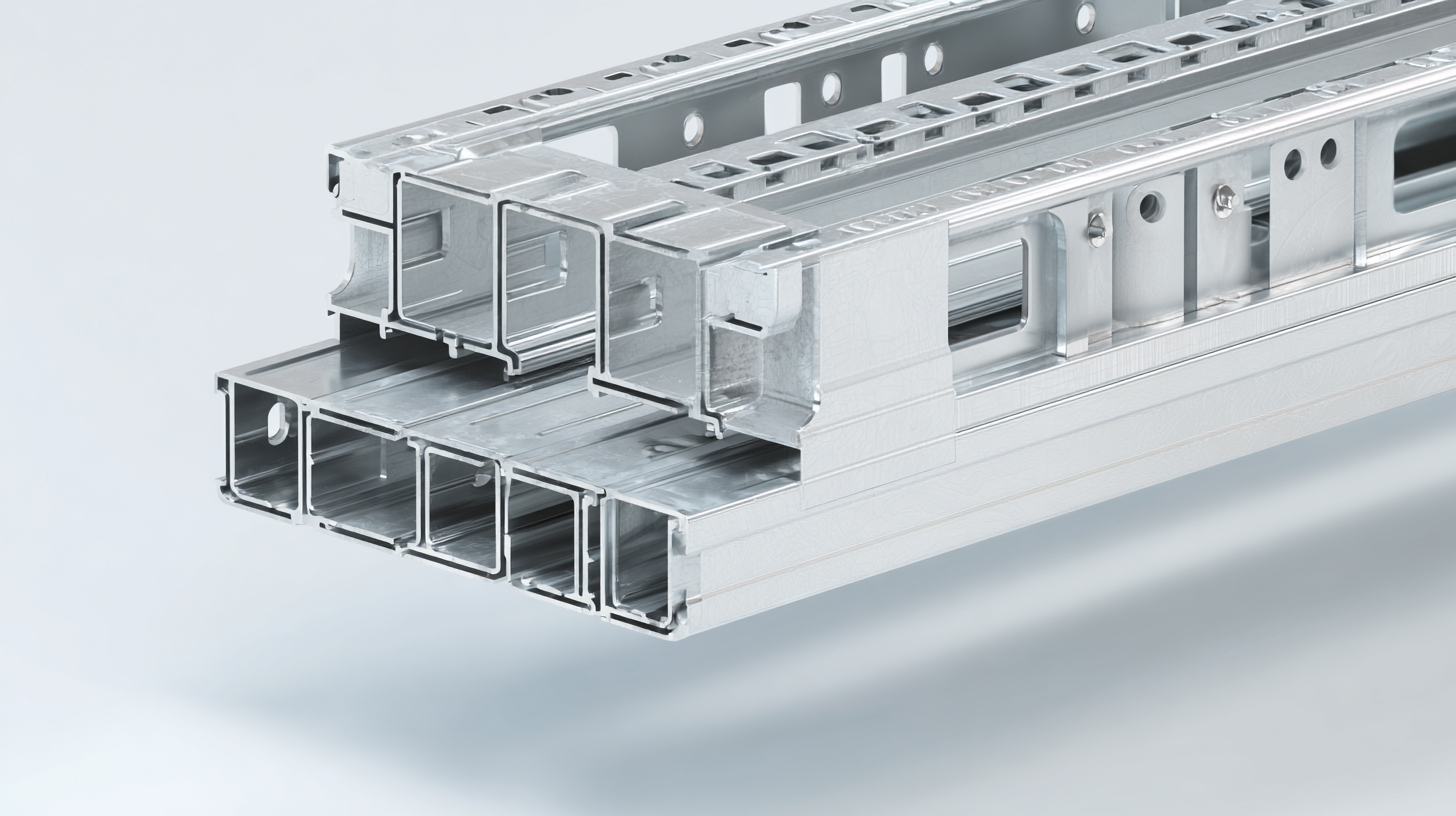

When selecting cable tray brackets for your projects, several key factors must be taken into consideration to ensure optimal performance and efficiency. First and foremost, the material of the brackets plays a critical role; options include steel, aluminum, and plastic, each offering distinct advantages based on environmental conditions and load requirements. For example, galvanized steel is often preferred for outdoor installations due to its corrosion resistance, while aluminum is lightweight and suitable for indoor applications where weight is a concern.

Another important aspect is the load capacity of the brackets. It’s essential to assess the weight of the cables that will be supported and choose brackets that can handle that load without compromising safety. Additionally, the spacing and configuration of the brackets should be aligned with the specific layout of the cable trays, ensuring they provide adequate support while facilitating easy access for maintenance. Lastly, compliance with relevant industry standards and local codes should not be overlooked, as these guidelines ensure the reliability and safety of your installation over time.

Maximizing Efficiency: Cable Tray Bracket Selection Factors

Analyzing Load Capacity: Ensuring Structural Integrity

When selecting cable tray brackets for your projects, analyzing load capacity is crucial to ensure structural integrity. The load capacity of a cable tray system is determined by the materials used, design specifications, and environmental factors. Properly evaluated load-bearing capabilities can prevent failures and extend the lifespan of the installation.

Tips: Always consult the manufacturer's specifications to understand the maximum load each bracket can support. Conduct a thorough assessment of the total weight of cables and any additional equipment. Consider any future expansions that might increase weight and require stronger supports.

Additionally, pay attention to the spacing of the brackets. Adequate spacing not only provides optimal support but also allows for proper air circulation and reduces stress on the cables. Ensuring that brackets are installed at recommended intervals will significantly enhance the overall stability of your cable tray system.

Tips: Utilize standardized spacing recommendations whenever possible and factor in the weight distribution of the cables when determining bracket placement. This proactive approach can save time and resources while safeguarding against potential safety hazards.

Installation Best Practices for Optimal Cable Tray Performance

Choosing the right cable tray brackets is essential for ensuring optimal installation and performance of cable trays in any project. When focusing on installation best practices, it’s important to consider factors such as load capacity and compatibility with the cables being used. Proper alignment and secure fastening of the brackets minimize the risk of sagging or misalignment, which can impede airflow and accessibility for future adjustments or maintenance.

In addition to hardware selection, effective cable management practices play a pivotal role in enhancing overall performance. This includes organizing cables neatly within the trays, utilizing cable ties or clips to prevent tangling, and ensuring that there is enough space for airflow to prevent overheating. Keeping these best practices in mind will not only improve the efficiency of your cable tray systems but also contribute to a cleaner and more professional appearance in any work environment. Proper installation and management techniques ultimately lead to a lasting and reliable infrastructure.

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Cable Tray Brackets for Your Projects

| Bracket Type | Material | Load Capacity (lbs) | Best For | Installation Difficulty |

|---|---|---|---|---|

| L-Shaped Bracket | Steel | 100 | Heavy-Duty Applications | Moderate |

| Wall Bracket | Aluminum | 75 | Wall-Mounted Trays | Easy |

| Folding Bracket | Plastic | 50 | Lightweight Use | Easy |

| Corner Bracket | Stainless Steel | 150 | Corner Installations | Moderate |

| Adjustable Bracket | Galvanized Steel | 120 | Versatile Applications | Difficult |

Maintaining Your Cable Tray Brackets: Tips for Longevity and Efficiency

When selecting cable tray brackets, it’s crucial to consider not only their initial installation but also how to maintain them for long-term efficiency. Proper maintenance can significantly enhance the lifespan of your cable tray system, ensuring it operates smoothly throughout your projects.

One vital tip for maintaining your cable tray brackets is to conduct regular inspections. Look for signs of corrosion or damage, as these can compromise structural integrity. Additionally, ensure that any bolts or fasteners are tightened according to the manufacturer’s specifications. A loose bracket can lead to misalignment and stress on cables, which may cause downtime or damage.

Another important tip is to keep your cable trays organized and free from excess weight. Overloading can strain the brackets and lead to premature wear. Use cable ties and clips to secure cables adequately, preventing movement and reducing wear on the brackets. Additionally, ensure that your installation site is clean and dry to prevent moisture buildup, which can also shorten the lifespan of your brackets. By following these maintenance tips, you can ensure that your cable tray brackets remain efficient and durable for all your projects.

Related Posts

-

China Leads the Global Market with Best Cable Tray Covers for Unmatched Quality

-

7 Compelling Reasons to Choose the Best Cable Tray Desk for Your Workspace

-

Exploring Cable Tray Wire Innovations at the 138th China Import and Export Fair in 2025

-

Exploring the Benefits and Innovations of Aluminum Cable Trays in Modern Electrical Installations

-

Innovative Solutions for Cable Management Issues in Power Plant Applications Using Best Wire Tray

-

How to Select the Best Wire Mesh Cable Tray for Your Industrial Needs