For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

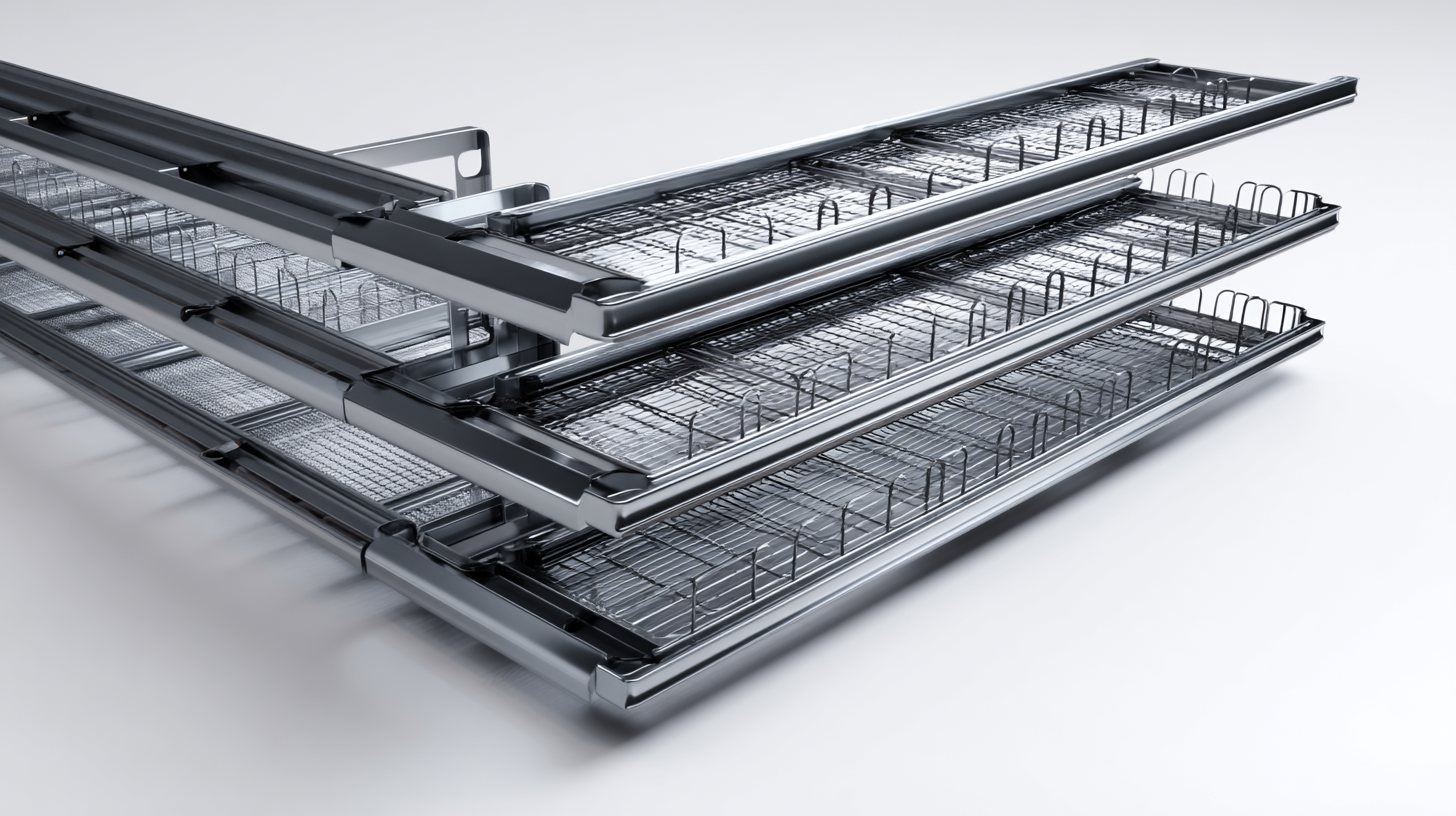

Maximizing Space Efficiency with Innovative Basket Cable Tray Designs

In the pursuit of enhanced space efficiency within electrical installations, the adoption of innovative basket cable tray designs has emerged as a pivotal solution. According to a report by MarketsandMarkets, the global cable tray market is expected to reach USD 5.5 billion by 2026, growing at a CAGR of 5.3% from 2021. This surge in demand underlines the essential role of efficient cable management systems, particularly in commercial and industrial applications.

The basket cable tray, known for its inherent versatility and ease of installation, allows for optimal airflow and minimizes clutter, making it a preferred choice among engineers and project managers. As the need for effective space utilization becomes increasingly critical in the face of rapid urbanization and technological advancements, innovative designs in basket cable tray systems stand out as key contributors to achieving operational efficiency and sustainability in electrical infrastructure.

Innovative Materials for Enhanced Durability in Basket Cable Tray Designs

Innovative materials play a pivotal role in enhancing the durability and efficiency of basket cable tray designs. Contemporary advancements in materials science have led to the development of high-strength alloys, corrosion-resistant coatings, and lightweight composites, which are not only improving the lifespan of cable trays but also their performance in demanding environments. According to a recent industry report by MarketsandMarkets, the global cable tray market is projected to reach $6.47 billion by 2025, highlighting a growing demand for durable solutions that can withstand extreme conditions and ensure reliable cable management.

When selecting materials for basket cable trays, consider using galvanized steel or aluminum, which offer significant resistance against rust and wear. Additionally, investing in trays with UV-resistant coatings can prevent degradation caused by sunlight, thereby extending their usability in outdoor applications.

**Tip:** Always evaluate the load capacity of the basket tray according to your unique installation needs. Ensure that the chosen material aligns with the environment's specific conditions, such as exposure to moisture or chemicals, to maximize efficiency and longevity. Using a combination of innovative materials can significantly reduce maintenance costs over time.

Ergonomic Configurations to Optimize Cable Management in Limited Spaces

In today's fast-paced technological landscape, effective cable management is essential, especially in compact environments. Innovative basket cable tray designs have emerged as a solution to maximize space efficiency while ensuring ergonomic configurations that cater to both functionality and accessibility. According to the National Electrical Manufacturers Association (NEMA), improper cable management can lead to a 30% increase in maintenance time, making efficient design not just a matter of aesthetics but also of operational efficiency.

Basket cable trays, with their open architecture, facilitate improved air circulation and reduced overheating risks, which is particularly critical in confined spaces. As highlighted in a report by the Cabling Installation & Maintenance publication, studies show that implementing modular designs can save up to 25% in installation time compared to traditional cable management systems. These innovations not only streamline cable organization but also enable easier access for maintenance and upgrades, supporting a more ergonomic work environment that enhances productivity and reduces physical strain on technicians handling cable repairs and adjustments.

Basket cable trays, with their open architecture, facilitate improved air circulation and reduced overheating risks, which is particularly critical in confined spaces. As highlighted in a report by the Cabling Installation & Maintenance publication, studies show that implementing modular designs can save up to 25% in installation time compared to traditional cable management systems. These innovations not only streamline cable organization but also enable easier access for maintenance and upgrades, supporting a more ergonomic work environment that enhances productivity and reduces physical strain on technicians handling cable repairs and adjustments.

Sustainable Practices in the Production of Basket Cable Trays

The production of basket cable trays has seen significant advancements that prioritize sustainability without compromising on functionality. Innovative designs not only enhance space efficiency but also incorporate eco-friendly materials and manufacturing processes. Many manufacturers are now opting for recycled metals and non-toxic finishes that reduce environmental impact while maintaining durability. This shift towards sustainable practices reflects a growing awareness in the industry about the need to minimize waste and energy consumption.

Furthermore, the integration of modular designs in basket cable trays allows for easy adaptability and reconfiguration, aligning with sustainable architectural practices. These designs facilitate efficient installations and modifications, which can lead to reduced material use over time. By embracing modern production techniques such as 3D printing and automation, manufacturers can streamline operations and further lessen their ecological footprint. Ultimately, this commitment to sustainability not only benefits the environment but also enhances the long-term viability of the cable tray systems in diverse applications.

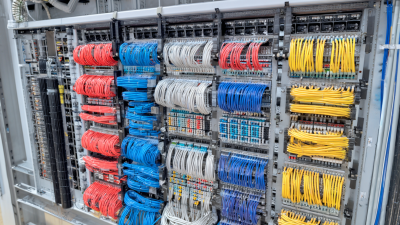

Comparative Analysis of Traditional vs. Modern Basket Cable Tray Systems

In the quest for optimal space utilization in industrial and commercial settings, the design and functionality of cable trays have evolved significantly. Traditional basket cable tray systems, often made of metal mesh, have been a standard solution for organizing and supporting electrical cables. These systems offer simplicity and ease of installation, but they can sometimes fall short in terms of adaptability and resistance to environmental factors. Their rigid structure may limit the ability to efficiently route cables in complex layouts, leading to potential occupancy issues and reduced airflow.

In contrast, modern basket cable tray designs incorporate innovative materials and customizable features that enhance space efficiency. With options like lightweight plastic composites and modular configurations, these contemporary systems can be tailored to fit various installation scenarios, accommodating changing technology demands. Additionally, the design improvements in modern tray systems promote better heat dissipation and easier access for maintenance purposes. This flexible approach not only maximizes the use of available space but also supports a more organized and efficient cable management strategy, ultimately leading to lower operational costs and improved system reliability.

Comparative Analysis of Traditional vs. Modern Basket Cable Tray Systems

Future Trends: Smart Technology Integration in Cable Tray Designs

The integration of smart technology in cable tray designs is set to revolutionize the electrical infrastructure landscape. As the demand for more efficient space management increases, innovative basket cable trays are evolving to accommodate smart features that enhance their functionality. These designs can incorporate sensors that monitor cable temperature, load, and environmental conditions. This real-time data collection allows for proactive maintenance and troubleshooting, reducing downtime and optimizing operational efficiency.

Additionally, with advancements in IoT (Internet of Things) technology, cable trays can now connect to centralized management systems. This integration enables users to monitor the performance of electrical systems remotely, ensuring that potential issues are addressed before they escalate. The future of cable tray designs will likely see the merging of aesthetics with high-tech capabilities, allowing for seamless installation that does not compromise on design or space efficiency. As these smart cable trays become more commonplace, they will play a crucial role in the smart buildings of tomorrow.

Maximizing Space Efficiency with Innovative Basket Cable Tray Designs - Future Trends: Smart Technology Integration in Cable Tray Designs

| Design Feature | Description | Expected Impact (%) | Implementation Year |

|---|---|---|---|

| Modular Design | Allows for customizable configurations and easy installation | 25 | 2024 |

| Wireless Monitoring | Integration of sensors to monitor load and temperature | 35 | 2025 |

| Lightweight Materials | Use of advanced composites to reduce weight without sacrificing strength | 20 | 2023 |

| Self-Adjusting Trays | Trays that can adjust spacing based on load analysis | 30 | 2026 |

| Eco-Friendly Options | Sustainable materials and production processes | 40 | 2027 |

Related Posts

-

Understanding Import and Export Certifications for the Best Stainless Steel Cable Tray

-

Choosing the Right Metal Cable Tray for Your Specific Needs

-

7 Essential Tips for Choosing the Right Cable Tray Cover to Enhance Safety and Efficiency

-

Exploring the Benefits and Innovations of Aluminum Cable Trays in Modern Electrical Installations

-

How to Choose the Right Cable Basket for Your Project

-

Ultimate Guide to Electrical Cable Trays: Optimizing Efficiency and Safety in Modern Installations